OIL-SEPARATOR-INSTALLATION KITS according EN858

FREYLIT Oil Separators (Mineral Oil and Residual Oil Separator) are designed to the exact specification and requirements of our client. The modular plate-pack system is the perfect solution for oil/water separation. FREYLIT Corrugated Coalescent Plate Separators are the most economic method of treating process water efficiently.

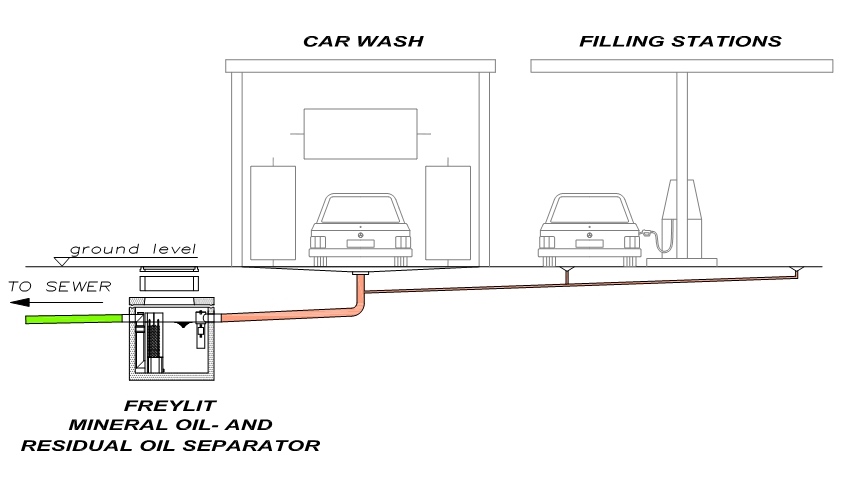

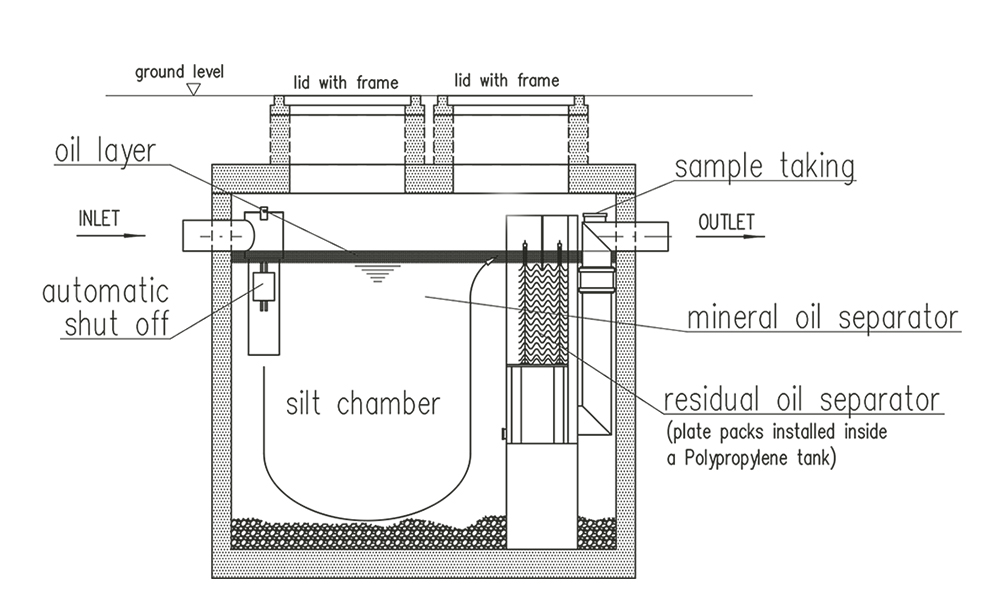

The FREYLIT Mineral Oil and Residual Oil Separator type M+R_RE is a compact unit with an integrated silt chamber, mineral oil separator, residual oil separator, automatic shut-off and sampling point. It is used for separating mineral oils from waste water.

With the technology of the FREYLIT oleophilic, horizontal non-corroding corrugated coalescent plates made of polypropylene, effluent oil concentration is well below government requirements, without having to resort to any secondary treatment processes.

Any oil from chemically produced stable emulsions or soluble oils can not be separated by mechanical oil separators.

Applications

- Service Stations (Gas Stations)

- Car Maintenance Workshops

- Truck Maintenance Workshops

- Bus maintenance workshops

- For parking areas on airports

- For parking areas on shopping centres (super markets)

- For parking areas on train stations

- Car Dealerships

- Tram Maintenance Workshops

- Train Maintenance Workshops

- Military Vehicle Maintenance Workshops

- For parking areas on tram stations

- For highways in a water protection area

- For parking areas on military casern

- For parking areas on railway stations

Key benefits

- OIL OUTLET CONCENTRATION below 5 ppm (5 mg/Liters) - CLASS 1 separators

- GREATEST ADVANTAGE OF THE FREYLIT OIL SEPARATOR: The efficiency of the separation process can be increased, without changing the tank or any additional civil work. The DISTANCE BETWEEN OUR CORRUGATED COALESCENT PLATES can be switched from 12 mm to 6 mm by turning the same plates 180°, to increase the efficiency of the separation process "FOUR TIMES"!

- CORRUGATED HORIZONTAL COALESCENT PLATES (material Polypropylene) - LIFETIME OF MINIMUM 20 YEARS

- Over 20.000 FREYLIT OIL WATER SEPARATORS in operation worldwide.

- More than 90% of all gas stations in Austria equipped with FREYLIT oil separators.

- FREYLIT oil separators meet the strictest European and international quality standards, such as the European Standard EN858.

How it works

The oil contaminated water flows by gravity into the underground oil water separator tank.

Inside this tank the FREYLILT Installation kit is installed.

The waste water enters the silt chamber section of the FREYLIT oil separator through an inlet pipe with integrated automatic shut off. Then the waste water flows into the oil separator section. Since the design provides for an inlet deflector, the oil/water flow is deflected, which generates a current in the direction of the oil collection layer (separator surface). Consequently, the big oil drops rise faster towards the oil layer. Then, the water (which still contains oil droplets) flows through the PLATE PACK SECTION of the separator. Oleophilic, horizontal non-corroding corrugated coalescent plates are used for removing the residual oil.

A submersed outlet pipe prevents the oil collected on the surface off the water to exit from the oil separator.

A sample taking point is located at the top of the submersed outlet pipe. The sample taking point can be accessed when the screw on lid is removed.

Technical specifications

- Flow rates from 2 Liters/second up to 100 Liters/second

- Automatic shut off if an oil layer of 20 cm has been reached inside the separator

- Residual oil separation with special CORRUGATED HORIZONTAL PLATE PACKS

- OIL OUTLET CONCENTRATION BELOW 5 mg/liter (ppm)

- Designed according European standard EN858

- minimum Lifetime 20 years

FREYLIT KNOW – HOW

Technology

All FREYLIT oil separators are based on the same technology using special oleophilic, non-corroding, corrugated coalescing plates

Key Benefits

- Most efficient oil-water separation worldwide

- 4x more efficient than conventional oil separators

- Oil outlet concentration below 5 mg/l (ppm)

- Significant cost savings

- Virtually no maintenance

- minimum Lifetime 20 years