WASH-WATER-RECYCLING-SYSTEMS

The recovery or treatment of dirty water that arises in vehicle washing systems is often required by law. With FREYLIT recycling systems, you not only meet legal standards and regulations without any problems, you also significantly reduce consumption and costs for fresh water and cleaning agents. This means savings of up to 90 percent on fresh water and cleaning agents. By reducing fresh water consumption by up to 90 percent tremendous savings can be realized with FREYLIT water recycling systems.

Applications

FREYLITs Wash-Water-Recycling systems can be used for any kind of vehicle washing.

For example: cars, trucks, buses, trains, golf carts, air planes, military vehicles and many more.

Key benefits

- 90% WATER SAVING

- SUITABLE FOR ALL TYPES OF VEHICLE WASHING MACHINES ON THE WORLD MARKET

- WATERTREATMENT "WITHOUT CHEMICALS" BY USING AN ELECTRICAL-PHYSICAL PRINCIPLE

- MINIMUM MAINTENANCE INVESTMENT (2 times per year) MAX. 60 MINUTES PER MAINTENANCE

- NO CONSUMABLE MATERIALS (CHEMICALS, FILTERS...)

Technical specifications

- CAPACITIES: FROM 30 litres/min to 1000 litres/min

- multistage filtration without the need of replacing filters

- free of bad Odour due to our own developed two stage degerming process

- Bioburden below hygienic requirements

- Recycling rate more than 90%

- Meets all requirements according ÖNORM B5107

How it works

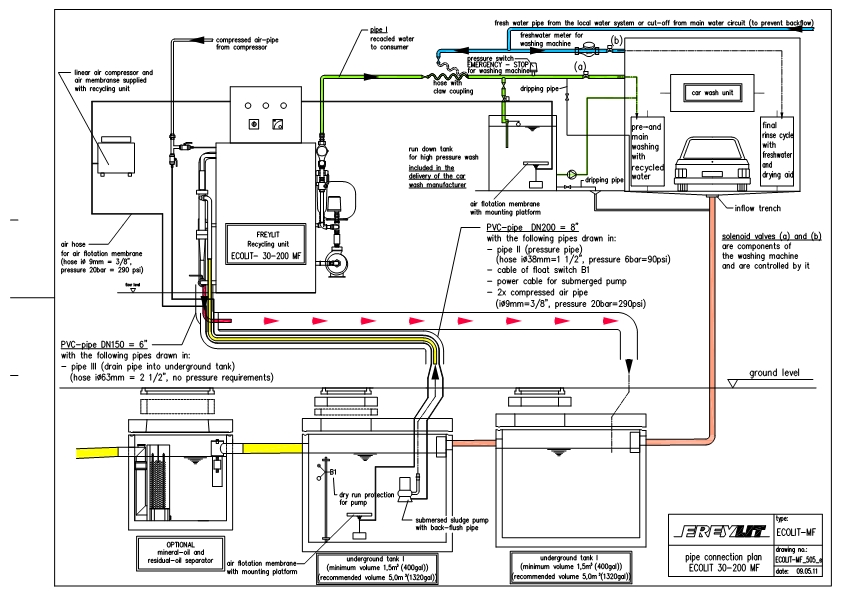

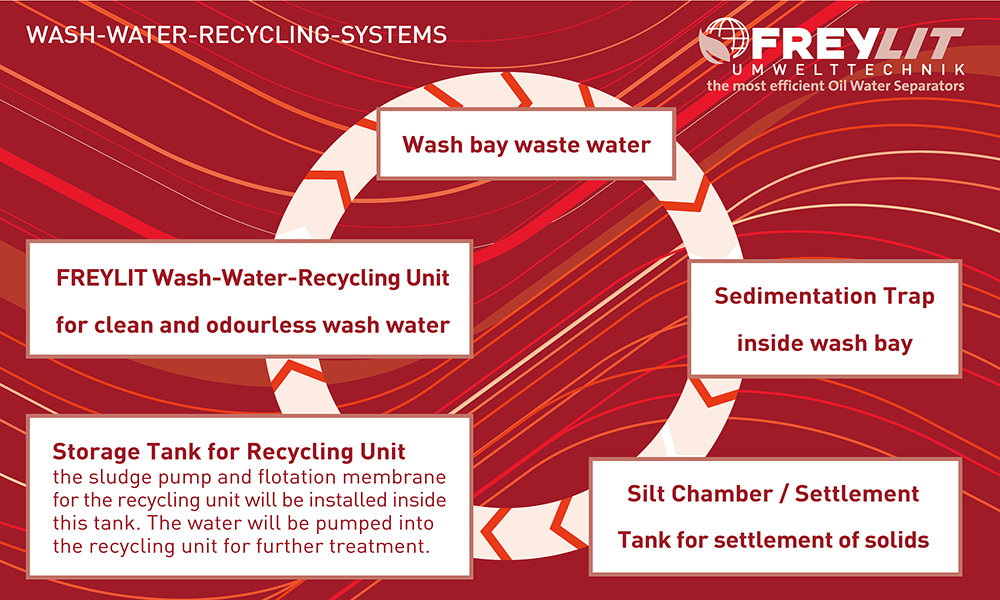

The uses wash water flows from the wash bay, through the Sedimentation Trap into the Silt chamber. Solids will settle in this tank and the water will overflow into the storage tank. Via a submersible pump, installed in this tank, the water will be pumped into the FREYLIT Wash-Water-Recycling Unit.

The Wash Water will be filtered by hydro cyclones and passes our two-stage chemical free degerming process, before entering the reactor tank of the recycling unit.

The degermed and prefiltered water will be stored inside this reactor tank. With our dissolved air flotation smaller floating dirt particles will be separated to the water surface of the reactor tank and periodically drained back into the silt chamber.

The cleaned and Odour free water will be pumped out of the reactor tank on demand of wash water for the wash bay.

An optional fine filtration with automatic back flush can be added on request.

Now the process will start all over again and again.

Schematic diagram